Piezo Inkjet Printing with UV Curing on Continuous Webs

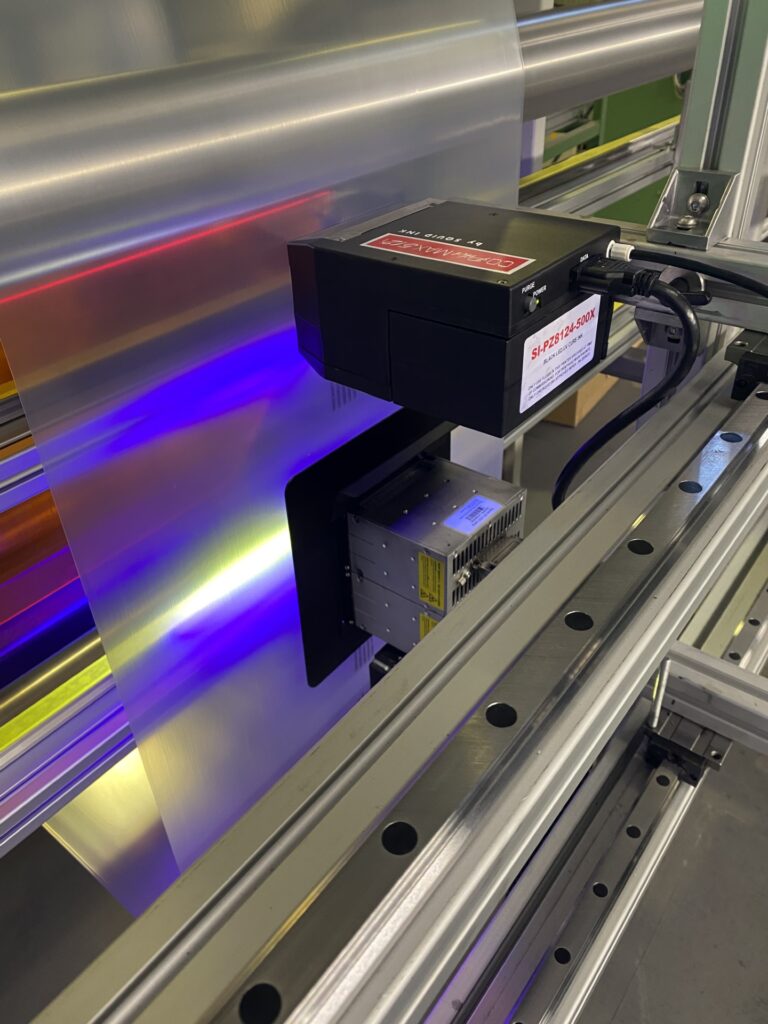

At Pacific Labeling we know manufacturers are looking for smarter faster and more efficient ways to bring products to market. That is why we partner with Squid Ink to deliver cutting edge solutions like the CoPilot family of piezo inkjet printers paired with UV curable inks. This combination allows businesses to print durable high resolution images and variable information directly onto continuous web materials with speed and accuracy.

Why Piezo Inkjet Printing Matters

Piezo inkjet technology uses advanced printheads that fire microscopic drops of ink with extreme precision. The result is crisp barcodes clear text and vibrant graphics that meet the high standards of today’s packaging requirements. Unlike flexographic printing which locks you into a single image until the press is stopped piezo inkjet allows instant image changes. Every impression can be unique whether it is a serialized barcode a compliance mark or a custom promotional graphic.

This ability to switch on the fly eliminates downtime for plate changes or cleanup and makes short runs just as cost effective as large volume jobs. It gives manufacturers the freedom to adapt quickly to new labeling requirements without slowing production.

The Advantage of UV Curable Inks

UV curable inks are the key to durability and efficiency. Instead of waiting for ink to dry the printed image cures instantly under ultraviolet light. The cured ink forms a tough layer that is resistant to scratching water fading and chemicals. That means your labels and films are ready to handle tough environments as soon as they leave the press.

UV inks also eliminate the need for flammable solvents and reduce VOCs making the process cleaner safer and more environmentally friendly. Production lines benefit from faster throughput and safer working conditions while meeting sustainability goals.

Continuous Web Printing in Action

The combination of piezo technology and UV inks excels on continuous web materials such as:

• Paper stocks for variable data labeling

• Plastic films for flexible packaging and mailers

• Aluminum foils and metallic finishes for premium branding applications

Because curing is instant the line keeps moving without delay. The system is flexible enough to handle porous and non porous substrates giving you versatility across product categories.

Where This Technology Excels

Piezo inkjet with UV curing is already making an impact across industries:

• Flexible films – polyethylene sheeting, mail bags, waste bags, pouches

• Flexible packaging – snack wrappers, shrink sleeves, food pouches

• Labels – product labels, promotional labels, retail labels, variable data labels

• Food and beverage – dairy cartons, bakery packaging, beverage bottles, bags and films

• Pharmaceutical and medical – compliant legible labels for regulated industries

• Industrial labeling – rugged prints built to withstand extreme conditions

Key Advantages at a Glance

• High resolution graphics smooth gradients and fine detail

• Variable information for traceability serialization and branding

• Wide substrate versatility from porous paper to metallic foils

• Fast production speeds with instant UV curing

• Durable prints resistant to fading scratching and chemicals

• Cleaner eco friendly operation with low VOCs and solvent free inks

The Pacific Labeling Difference

Choosing the right equipment is only the first step. At Pacific Labeling we pair cutting edge technology with decades of experience in pressure sensitive labeling machinery and industrial printing systems. Our nationwide reach allows us to install train and support customers wherever they are.

We know uptime matters which is why our service team is dedicated to keeping your equipment running at peak efficiency. To make sure our customers see the benefits first hand we also offer a 14 day free trial program. This allows you to test the system in your own facility on your own products and experience the improvements in speed quality and flexibility before you commit.

Conclusion

Piezo inkjet printing with UV curing on webs is not just an upgrade. It is a new way to approach product labeling and packaging. With its ability to deliver high resolution graphics variable information instant curing and unmatched durability it offers manufacturers a competitive advantage in today’s fast moving markets.

Backed by Pacific Labeling’s service expertise and support this technology is more than equipment. It is a complete solution for businesses that want reliability flexibility and performance.

#PacificLabeling #SquidInk #InkjetPrinting #UVPrinting #LabelingSolutions #PackagingIndustry #ManufacturingSolutions #ProductionEfficiency #VariableData #CodingAndMarking #FoodAndBeverage #PharmaPackaging #FlexiblePackaging #IndustrialPrinting