Presented by Pacific Labeling & Integration

GS1 2D Coding for Modern Manufacturing

A Technical White Paper by Pacific Labeling & Integration

Executive Summary

Global supply chains are experiencing rapid transformation driven by increasing regulatory demands, retailer requirements and market expectations. Manufacturers across industries must deliver accurate high-speed product identification, maintain end-to-end traceability and supply rich data throughout the product life cycle. Traditional 1D barcodes cannot support the expanding density or variability of modern data requirements.

GS1 2D coding provides a compact, data-rich, globally standardized system that consolidates multiple data elements into a single symbol. GS1 2D formats support serialization, lot-level tracking, expiration management, weight information, manufacturing site identification and consumer-facing data in a space-efficient design that can be applied to primary, secondary and tertiary packaging.

This white paper presents an expanded analysis of GS1 2D coding, including:

- Detailed explanation of GS1 2D structure and Application Identifiers

- Comparison between 1D and 2D systems with scanning and data capacity discussions

- Engineering considerations for print quality, symbol integrity and verification

- Regulatory and retailer-driven requirements accelerating adoption

- Use of GS1 2D across primary packaging, cases, pallets, e-commerce parcels and mailers

- Integration of GS1 2D with advanced coding technologies including:

- LEIBINGER CIJ printers

- Squid Ink CIJ systems

- Squid Ink DOD printers and piezo high-resolution printers

- Squid Ink VIPER TIJ printers

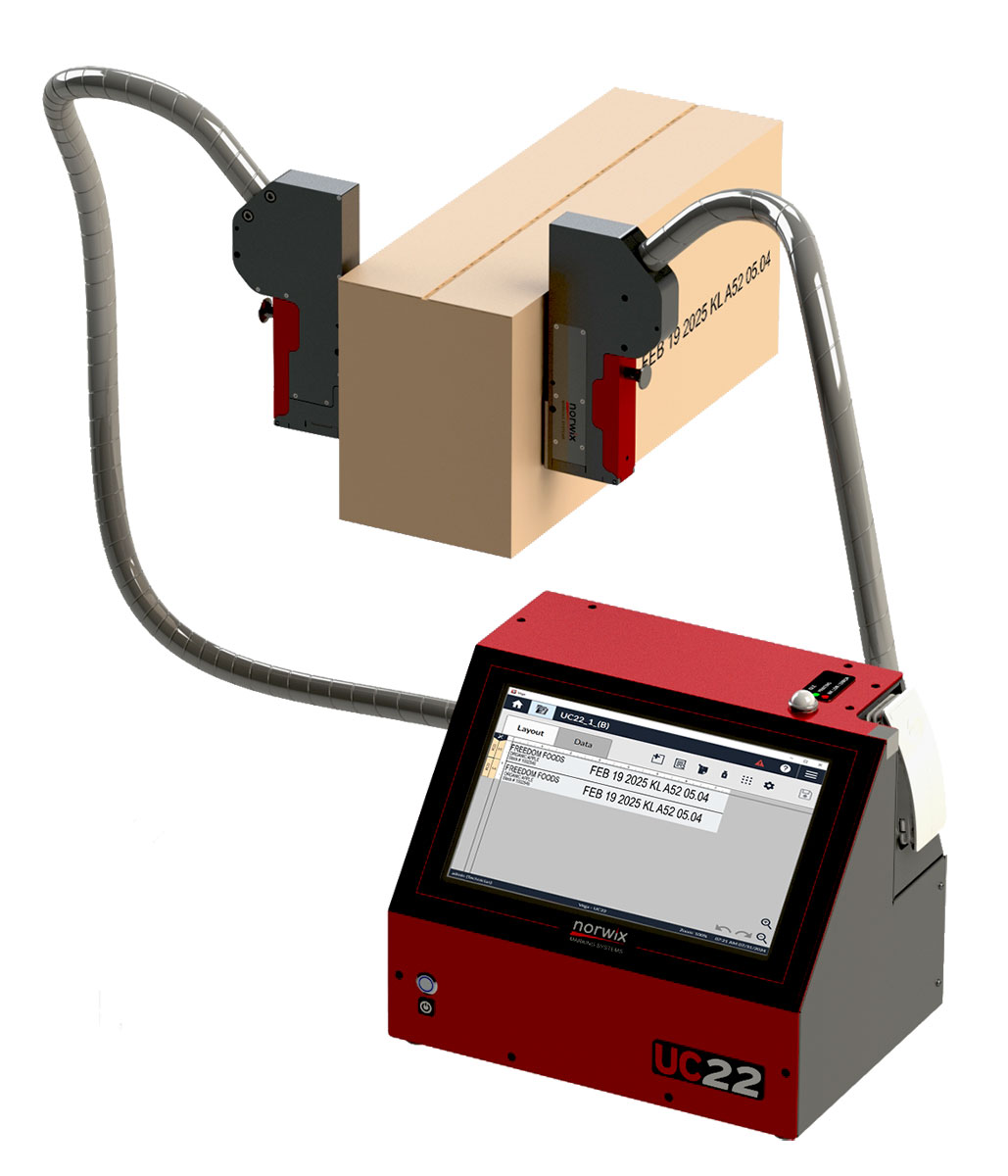

- Norwix UC22 TIJ printers

- Videojet 9560 print-and-apply systems

The paper concludes with a technical roadmap for full GS1 2D implementation, including line-level integration, verification and lifecycle support provided by Pacific Labeling & Integration.

1. Introduction to GS1 2D Coding

GS1 2D symbols represent the next generation of global product identification. Built on GS1’s established Application Identifier framework, these symbols encode structured data using two-dimensional patterns. Unlike linear symbols which are constrained by space and limited to a single key, GS1 2D codes integrate multiple identifiers into a compact mark that can be printed on nearly any package.

Common GS1 2D formats include:

- GS1 DataMatrix

- GS1 QR Code

- GS1 Digital Link QR

Each format uses a defined syntax to ensure global interoperability. These codes are readable by industrial fixed-mount scanners, handheld scanners, machine-vision systems, smartphone cameras and automated warehouse sortation equipment.

GS1 2D symbols support Application Identifiers such as:

- 01 — GTIN

- 10 — Batch or lot number

- 11 — Production date

- 17 — Expiration date

- 21 — Serial number

- 30 — Variable count

- 37 — Quantity

- 414 — Global Location Number of point of production

This structured approach ensures consistency across manufacturers, brands, distributors and retailers.

2. GS1 2D Codes Compared to 1D Barcodes

2.1 Data Capacity

A linear barcode can encode only a single data element such as a GTIN. Additional attributes require extra barcodes or human-readable fields which increases packaging clutter and slows scanning.

GS1 2D symbols can encode dozens of data fields within a single compact mark. This supports advanced capabilities such as:

- Per-item serialization

- Batch-level traceability

- Expiration date tracking

- Weight or volume capture

- Origin and regulatory fields

The ability to encode deep variable data is especially valuable for pharmaceuticals, food processing, fresh goods, cosmetics and industrial goods.

2.2 Scan Reliability and Error Correction

One of the strongest technical advantages of GS1 2D coding is its built-in error correction, which preserves readability even when:

- Symbols are partially damaged

- Packaging curves distort module geometry

- Ink spread or dot gain affects edges

- Symbols encounter abrasion during handling

- Surface irregularities reduce contrast

Error correction enables reliable decoding at high speeds and under industrial conditions, which reduces no-reads and manual inspection.

2.3 Space Efficiency

GS1 2D symbols pack significant data into very small areas which makes them ideal for:

- Vials and small rigid containers

- Bottles, jars and curved surfaces

- Flexible films and pouches

- Folding cartons and sleeves with high brand density

- Cases where space is shared between text, logos and codes

Compact symbols benefit packaging designers, manufacturers and retailers.

2.4 Consumer Transparency via Digital Link

GS1 Digital Link QR codes connect product packaging to cloud-based information systems. Consumers scan the code with a phone which leads to:

- Product instructions

- Authenticity verification

- Dietary or safety information

- Regulatory disclosures

- Recall notices

- Sustainability content

Manufacturers can update linked digital content without reprinting packaging.

3. Market, Retail and Regulatory Drivers

3.1 Retail Requirements

Large retailers are preparing systems for GS1 2D scanning at checkout. Benefits include:

- Higher-fidelity pricing and promotions

- Improved shrink control

- Faster and more accurate checkout

- Better inventory accuracy

- Enhanced returns processing

Manufacturers adopting GS1 2D early avoid costly redesigns later.

3.2 Pharmaceutical Serialization

Pharmaceutical regulations require printing standardized GS1 DataMatrix symbols with:

- GTIN

- Serial number

- Lot number

- Expiration date

The symbols must pass strict ISO 15415 quality grades. Manufacturers rely on CIJ and TIJ systems for small characters and tight tolerances.

3.3 Food and Beverage Traceability

GS1 2D supports:

- Real-time batch identification

- Temperature-controlled product tracking

- Farm-to-fork transparency

- Automated recall segmentation

High-speed printing is essential for beverage filling, protein processing and produce packing.

3.4 Anti Counterfeit and Gray Market Control

GS1 Digital Link QR can integrate with brand protection platforms enabling:

- Serialization

- Scan-location auditing

- Duplicate-scan detection

- Channel control

This helps authenticate premium goods such as spirits, cosmetics and supplements.

4. Printing Technologies for GS1 2D Marking

GS1 2D codes require high-resolution printing with accurate module geometry, consistent edge definition and stable contrast. Pacific Labeling & Integration deploys a full suite of technologies tailored to each application.

4.1 LEIBINGER Continuous Inkjet (CIJ)

CIJ is ideal for high-speed primary packaging. The LEIBINGER platform offers:

- Automatic nozzle sealing that prevents clogging

- Consistent drop formation at high line speeds

- Fast-drying inks for cold-room, wet and high-moisture zones

- Capability to print DataMatrix symbols on curved surfaces

- Strong adhesion on plastics, metals, glass and films

CIJ is widely used for beverage bottling, dairy, personal care, household goods and industrial products.

4.2 Squid Ink Continuous Inkjet

Squid Ink CIJ systems excel in harsh environments and on industrial substrates including:

- Flexible bags

- Industrial films

- Coextrusions

- Plastic containers

- Rubber, resin and construction materials

Squid Ink CIJ supports GS1 DataMatrix and GS1 QR printing where durability is essential.

4.3 Squid Ink DOD and Piezo High-Resolution Case Printing

Squid Ink DOD printers and piezo systems deliver large, high-contrast codes on corrugated:

- Case-level GS1 2D

- Multi-line text

- Graphics and logos

- Variable data

These systems can replace preprinted cases, reduce inventory and eliminate label waste.

4.4 Squid Ink VIPER Thermal Inkjet

The Squid Ink VIPER TIJ platform prints high-resolution GS1 2D codes on:

- Cartons

- Sleeves

- Display packaging

- Small-format boxes

TIJ’s clean operation and excellent DPI performance make it ideal for serialized packaging.

4.5 Norwix UC22 TIJ Printers

The Norwix UC22 TIJ system prints onto:

- Folding cartons

- Shipper cases

- Mailers and flats

It delivers label-equivalent resolution and crisp 2D codes ideal for warehouse scanning.

4.6 Videojet 9560 Print-and-Apply

The Videojet 9560 prints and applies GS1 compliant labels to:

- Cases

- Trays

- Bundles

- Pallets

Its tamp, wipe and corner-wrap options support serialized case and pallet labeling with dynamic data.

5. TIJ for High-Speed Mailing and Mailers

TIJ plays a critical role in mailing operations that require precision and high throughput.

5.1 Direct Mail and Addressing

TIJ prints GS1 2D codes on:

- Postcards

- Envelopes

- Booklets

- Self mailers

GS1 codes support:

- Sequence validation

- Delivery point verification

- Campaign tracking

5.2 Inserter and Bindery Lines

Inserters rely on GS1 2D for:

- Match-and-merge integrity

- Closed-loop tracking

- Automated reprint handling

TIJ integrates easily with vision systems for real-time validation.

5.3 E-commerce and Small Parcels

Thermal inkjet is used to print GS1 2D on:

- Flat mailers

- Cartons

- Return-ready packaging

Supporting increased automation in last-mile distribution.

6. Verification and Quality Assurance

GS1 2D codes require verification according to ISO 15415 and GS1 specifications. Key quality metrics include:

- Symbol contrast

- Modulation

- Decodability

- Axial non-uniformity

- Uneven print growth

- Quiet zone compliance

- Defect identification

Pacific Labeling & Integration deploys verification systems for CIJ, TIJ, DOD and print-and-apply to ensure compliance before products enter the supply chain.

7. End-to-End GS1 2D Integration Workflow

A successful GS1 2D deployment is not just about choosing a marking technology. It is an end-to-end engineering, quality and compliance process that touches equipment selection, data workflows, operational readiness and long-term lifecycle management. The following expanded workflow mirrors how top-tier manufacturers roll out GS1 2D programs across CIJ, TIJ, DOD and print and apply systems in high speed production environments.

7.1 Assessment

A GS1 compliant project begins with a complete evaluation of the production environment. This stage determines feasibility, defines print requirements and prevents costly redesigns later.

Key Assessment Activities

Substrate Analysis

• Review the exact material being printed corrugate, flexible film, paperboard, PET, HDPE, foil laminates and coated surfaces

• Determine ink adhesion requirements and curing behavior

• Identify surface energy challenges, texture, porosity and anti fog coatings

Packaging and Product Format Evaluation

• Identify primary, secondary and tertiary package levels

• Measure curved surfaces, recessed print areas, pre applied label zones and shrink sleeve movement during application

• Confirm available print real estate for GS1 DataMatrix, GS1 QR or GTIN plus AIs

Line Speed and Throughput Study

• Evaluate conveyor speed, dwell time, gap distance and SKU mix

• Determine print resolution required at maximum line speed

• Validate that the technology can maintain print integrity at peak throughput

Environmental Conditions

• Temperature, humidity, vibration, dust, washdown, solvent exposure

• Determine enclosure needs, air filtration, positive pressure housings or IP rated equipment

Camera and Verification Requirements

• Decide if inline grading (ISO/IEC 15415 for 2D, 15416 for 1D) will be required

• Define scan distance, angle of illumination and mounting options

The goal of this phase is to create a specification document that guides every downstream decision.

7.2 Printer Selection

Once the environment is fully understood, the correct print technology can be matched to the application. The decision is based on GS1 requirements, code durability, scan reliability and production economics.

How Printer Types Are Matched

CIJ (Continuous Inkjet)

• Best for bottles, curved surfaces, small characters and high speed lines

• Ideal for GTIN, lot, date and basic GS1 AIs

• Works on difficult substrates (PET, glass, metal cans)

TIJ (Thermal Inkjet)

• Excellent for high resolution GS1 DataMatrix and GS1 QR at moderate to high speeds

• Works on cartons, paperboard, labels and porous or semi porous materials

• Cartridges allow fast changeover between inks (aqueous or solvent)

DOD / Hi-Res Piezo

• Used for large GS1 codes on corrugate or secondary packaging

• Supports larger print heights, crisp edges and deep contrast for long range scanning

Print and Apply Label Systems

• Required when substrates are non printable or require compliant label placement

• Best for variable data shipping labels, serialized cases, multipacks and pallet labeling

Selection Criteria

• Required symbol type (GS1 DataMatrix, GS1 QR, GS1-128, 1D UPC/EAN)

• Print area limitations

• Required module size for scanner compatibility

• Required permanence scratch resistance, moisture resistance, abrasion durability

• Total cost of ownership and ink consumption

The result is a technology match that ensures the GS1 symbols remain readable, durable and compliant.

7.3 Template Engineering

This is the heart of GS1 integration. Template engineering ensures that every printed code meets GS1 standards, encodes the correct data and maintains consistency across shifts, lines and facilities.

Core Template Engineering Steps

GS1 Application Identifier Mapping

• Define which AIs are required for the SKU (01 GTIN, 10 Lot, 17 Expiration, 21 Serial, 11 Production Date, 30 Count, 37 Quantity, 414 GLN, etc.)

• Confirm correct data formats, fixed vs variable lengths and check character rules

Data Serialization Logic

• Choose between incremental, randomized, batch or externally supplied serials

• Establish rollover logic and uniqueness validation

• Integrate with MES, ERP or cloud serialization systems where required

Dynamic Field Development

• Create placeholders for dates, shifts, batch changes, line numbers or customer specific attributes

• Ensure correct zero padding, date formats (YYMMDD or YYYYMMDD) and internal compliance rules

Symbol Layout and Print Geometry

• Set module size, X dimension, quiet zone, error correction level, print orientation and contrast

• Validate that the symbol fits available packaging space

Printer Integration

• Map data to CIJ, TIJ, DOD or labeler control software

• Ensure synchronized triggers, encoder inputs and reject logic

• Build fallback templates for manual rework or reprint stations

Template engineering guarantees consistency and reduces operator error.

7.4 Operator Training

Operators play a critical role in GS1 compliance. Comprehensive training reduces downtime, prevents coding errors and ensures every printed symbol is readable across the supply chain.

Training Areas

Job Setup and Changeovers

• Selecting the correct GS1 template

• Verifying the encoded data on screen and on printed samples

• Adjusting print height, standoff, focus and print density for each SKU

Quality Checks and Verification

• How to use handheld scanners or inline vision systems to grade prints

• Identifying defects such as missing modules, low contrast, stretching or jitter

• Understanding reject station logic

Routine Maintenance

• CIJ nozzle cleaning, ink makeup management and startup shutdown procedures

• TIJ cartridge replacement, alignment and maintenance of porous vs non porous inks

• DOD purge cycles, filter checks and cleaning requirements

Troubleshooting Basics

• Diagnosing poor adhesion, smearing, over spraying or misalignment

• Identifying environmental issues such as condensation or dust contamination

Training is standardized to ensure every operator on every shift produces compliant GS1 codes.

7.5 Lifecycle Support

Long term reliability is critical for GS1 adoption. Once the system is live, the workflow transitions into ongoing support, proactive maintenance and continuous improvement.

Lifecycle Support Components

Preventive Maintenance

• Scheduled deep cleaning, filter replacements and ink system checks

• Software and firmware updates to maintain symbol quality and stability

Remote Support and Diagnostics

• Troubleshooting print quality, template errors and data path issues

• Rapid response to line stoppages and operator issues

Print Quality Audits

• Periodic grading of GS1 2D and 1D codes (ISO/IEC 15415, 15416)

• Trend analysis to identify emerging issues

• Line certification for customers or regulatory audits

Template Updates and Data Governance

• Adding new AIs for customer or regulatory changes

• Updating serialization logic

• Ensuring templates remain aligned with GS1 guidelines

Spare Parts and Consumables Planning

• Stocking inks, cartridges, filters and printheads for uninterrupted production

• Forecasting based on seasonal or SKU cycle changes

Lifecycle support ensures the entire GS1 ecosystem stays compliant, durable and production ready for years.

8. Benefits of GS1 2D with Pacific Labeling Technologies

Implementing GS1 2D barcodes delivers significant operational, regulatory and commercial advantages, especially when paired with Pacific Labeling’s integrated printing technologies and engineering support. These benefits span the entire supply chain from unit-level identification to pallet-level aggregation.

8.1 Full Traceability from Unit to Pallet

GS1 2D symbols unlock item-level serialization and structured data packaging, allowing manufacturers to track every step from production to distribution.

Traceability Enhancements

• Unit-level GTIN, lot, time stamp and serial tracking

• Case-level aggregation with parent child data relationships

• Pallet-level SSCC labels linked directly to case and unit records

• Rapid reconstruction of product movement during investigations

This enables complete visibility across manufacturing, warehousing and retail networks.

8.2 Higher Scan Accuracy and Reduced No Reads

GS1 DataMatrix and GS1 QR offer superior scanning performance compared to legacy 1D barcodes.

Operational Advantages

• Stronger readability in low contrast environments

• Error correction capability compensates for damage or distortion

• Reliable scanning at high line speeds and long scan distances

• Higher success rates with automated warehouse systems

Improved scan accuracy reduces rework, bottlenecks and manual exception handling.

8.3 Compliance with Global Regulations

Many industries now require GS1 compliant 2D codes to meet international traceability and serialization mandates.

Regulatory Alignment

• FDA DSCSA requirements for serialized pharmaceutical packaging

• EU FMD compliance for pharmaceutical products

• Produce traceability (PTI), fishery and meat industry frameworks

• Medical device UDI requirements under FDA and EU MDR

• Retailer driven 2D mandates including Walmart and global CPG standards

Pacific Labeling solutions ensure all printed codes conform to the GS1 standard, helping customers avoid compliance penalties.

8.4 Seamless Integration with CIJ, TIJ, DOD and Print-and-Apply

Pacific Labeling supports GS1 2D deployment across all major marking and labeling technologies, enabling consistent results regardless of packaging format.

Integration Capabilities

• CIJ for bottles, cans, pouches and curved surfaces

• TIJ for high resolution codes on cartons and paperboard

• DOD for large format case codes and high contrast corrugate marking

• Print and apply for variable shipping labels, pallet tags and multipack labeling

• Unified template management for consistent data across all devices

This multi technology coverage allows customers to standardize GS1 compliance across their entire product portfolio.

8.5 Digital Link Capabilities for Consumer Engagement

GS1 Digital Link transforms the 2D barcode into a gateway for digital experiences.

Digital Link Benefits

• Redirect consumers to product pages, safety information or promotions

• Enable dynamic content updates without changing the packaging

• Support loyalty programs, authenticity checks and brand protection

• Reduce the need for multiple QR codes on the same package

Manufacturers gain the ability to add marketing and compliance content using a single, standards based symbol.

8.6 Reduced Packaging Complexity

GS1 2D allows multiple data elements to be encoded into one symbol, reducing the need for separate labels, graphics or pre printed information.

Packaging Improvements

• Consolidation of date codes, batch codes and identifiers

• Reduced clutter on small packages

• Greater flexibility during artwork changes

• Less reliance on costly pre printed packaging materials

This gives manufacturers more agility and lowers total packaging cost.

8.7 Future Proofing Against Retailer Mandates

Major retailers are already transitioning to GS1 2D. Early adoption prevents costly last minute upgrades.

Retailer Trends

• Walmart, Kroger, Carrefour and others moving to 2D-only scanning

• Retail POS scanners increasingly optimized for 2D

• CPG brands encouraged or required to implement 2D for traceability

Deploying GS1 2D through Pacific Labeling ensures your operation is ready for evolving supply chain requirements.

8.8 Better Recall Targeting

Traditional recalls often affect entire production ranges due to limited traceability. GS1 2D enables finely targeted recall actions.

Recall Advantages

• Identification of only the affected serial numbers, lots or production windows

• Faster root cause analysis

• Reduced product loss and financial impact

• Greater transparency with retailers and regulators

This is particularly beneficial for food, beverage, pharmaceutical and nutraceutical manufacturers.

8.9 Improved Warehouse Automation

High resolution 2D codes streamline automated material handling, inventory management and logistics operations.

Automation Benefits

• Reliable scanning by robotic arms, ASRS and palletizers

• Better performance with vision systems and automated sortation

• Reduced cycle time for receiving, put away and picking

• More accurate case and pallet validation

GS1 2D enhances overall warehouse performance and supports Industry 4.0 automation initiatives.fits of GS1 2D with Pacific Labeling Technologies

- Full traceability from unit to pallet

- Higher scan accuracy and reduced no reads

- Compliance with global regulations

- Integration with CIJ, TIJ, DOD and print-and-apply

- Digital Link capabilities for consumer engagement

- Reduced packaging complexity

- Future-proofing against retailer mandates

- Better recall targeting

- Improved warehouse automation

9. Conclusion

GS1 2D coding is rapidly becoming the universal standard for product identification. Its compact design, data capacity and global structure make it ideal for modern manufacturing, retail and logistics. Pacific Labeling & Integration offers comprehensive GS1 2D integration using CIJ, TIJ, high-resolution case printing and print-and-apply labeling systems. With engineering expertise, template development, installation support and verification solutions, Pacific Labeling provides manufacturers with a complete, scalable platform for GS1 compliance.

References

GS1. “GS1 General Specifications.” GS1 Global Office.

GS1. “GS1 Digital Link Standard.” GS1 Global Office.

GS1. “Application Identifiers Standard.” GS1 Global Office.

FDA. “Drug Supply Chain Security Act.” U.S. Food and Drug Administration.

European Medicines Agency. “Falsified Medicines Directive Safety Features.”

ISO/IEC 15415. “Barcode Print Quality Test Specification.”

ISO/IEC 29158. “Direct Part Mark Quality Guideline.”

WHO. “Global Traceability Standards for Pharmaceuticals.”

McKinsey Global Institute. “Supply Chain Digitization and Traceability.”

Harvard Business Review. “Reducing Product Recalls through Digital Traceability.”