Presented by Pacific Labeling & Integration

Expanded White Paper: Squid Ink CoPilot DOD/Piezo Printers vs Major Competitors

Executive Summary

High-resolution Drop on Demand Piezo printers are rapidly replacing labels and low-resolution case coders for secondary packaging. These systems print GS1 barcodes, logos and text directly onto corrugate cases, trays and cartons. By removing preprinted labels and reducing consumables, they deliver fast payback and ensure supply chain compliance.

This paper evaluates the Squid Ink CoPilot series, including the CoPilot LT LongThrow, against major competitors such as Domino C-Series, Videojet 2351/2361, Matthews VIAjet T-Series and Markem Imaje 5800. It explores print quality, throw distance, ink system design, speed and maintenance to help operations leaders and engineers identify the most cost-effective and reliable solution.

Squid Ink CoPilot Overview

The Squid Ink CoPilot line uses Xaar piezo printheads to deliver high-resolution codes, logos and text. Each head can print up to 5.6 inches tall, and multiple heads can be stitched for larger applications. Print resolution ranges from 185 dpi x 205 dpi up to 360 dpi, more than adequate for GS1 barcodes. A 4.3-inch color touchscreen interface and Orion PC software make operation straightforward with Ethernet, USB or wireless connectivity.

Ink System and Flexibility

The CoPilot uses an open bulk ink system, unlike many competitors who rely on proprietary cartridges. This lowers cost per mark and increases flexibility. CoPilot supports water-based, solvent-based and UV-curable inks, allowing printing on porous corrugate, coated cartons, shrink-wrap films and plastics.

CoPilot Max LT LongThrow

For real-world conditions where cases may not align perfectly with the printhead, the CoPilot Max LT LongThrow offers a throw distance of up to 10–12 mm while maintaining code quality. Standard competitors often require tight 2–4 mm gaps, which increases stoppages when packaging is misaligned. LT solves this by widening the tolerance window, reducing rejects and downtime.

Competitor Landscape

High-resolution Piezo coders from Domino, Videojet, Matthews and Markem Imaje compete in the same space.

- Domino C-Series: Well-regarded for resolution but does not emphasize long-throw capability.

- Videojet 2351/2361: High-speed capable but requires tight print gaps of ~2 mm, limiting tolerance.

- Matthews VIAjet T-Series: Reliable resolution, publishes a throw distance of ~6.4 mm, better than Videojet but less than CoPilot LT.

- Markem Imaje 5800: Uses Touch Dry hot melt inks with gap controlled by slide assemblies, but tolerance remains narrow.

Feature Comparison Table

| Feature | Squid Ink CoPilot Series | Domino C-Series | Videojet 2351/2361 | Matthews VIAjet T-Series | Markem Imaje 5800 |

|---|---|---|---|---|---|

| Print Quality & Height | 185–360 dpi, up to 5.6 in per head, stitchable | 200 dpi, up to 70 mm | 180–300 dpi, up to 2.8 in | 200–300 dpi, up to 4 in | High-resolution Touch Dry |

| Long-Throw Capability | Up to 10–12 mm with LT | Not published | ~2 mm recommended | ~6.4 mm readable | ~3 mm typical |

| Speed | Up to 440 fpm at 150 dpi, 220 fpm at 300 dpi | High-speed | High-speed | 200–300 fpm typical | ~121 m/min |

| Ink System | Open bulk ink | OEM bulk or cartridges | OEM bulk | OEM bulk | OEM hot melt |

| Ink Types | Water, solvent, UV-curable | Water and solvent | Water and solvent | Water and solvent | Hot melt solid ink |

| Maintenance | Minimal | Regular | Regular | Regular | Regular |

| Scalability | Multihead stitching | Limited | Limited | Limited | Limited |

What These Differences Mean

Print Quality and Coverage

CoPilot supports 185–360 dpi, which exceeds minimum GS1 barcode readability requirements. With 5.6 inches of print per head and stitchable configurations, a single system can handle logos, multi-line text and large barcodes that would require multiple printers with competitors.

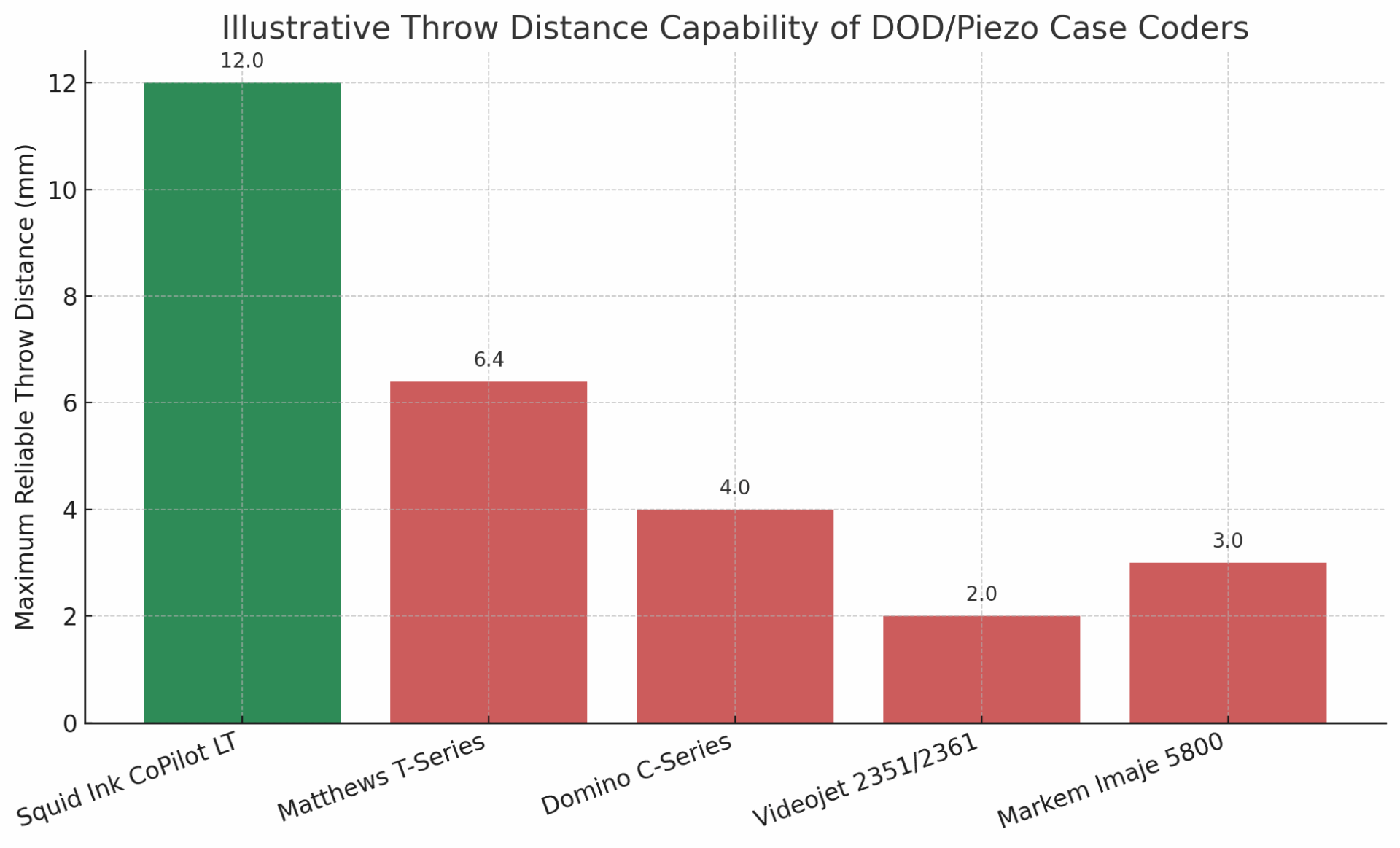

Throw Distance Tolerance

Throw distance is where CoPilot LT sets itself apart. At 10–12 mm, it more than doubles the tolerance of Matthews (6.4 mm) and far exceeds Videojet’s 2 mm recommendation. This means fewer stoppages caused by skewed, bulging or shrink-wrapped cases.

Illustrative Throw Distance Capability of DOD/Piezo Printers (mm)

This chart highlights how CoPilot LT’s tolerance reduces misprints and downtime in real production environments.

Speed and Throughput

CoPilot maintains barcode quality at 220 fpm with 300 dpi, which covers most secondary packaging needs. In long-throw mode, it continues to deliver readable codes at higher line speeds, reducing bottlenecks.

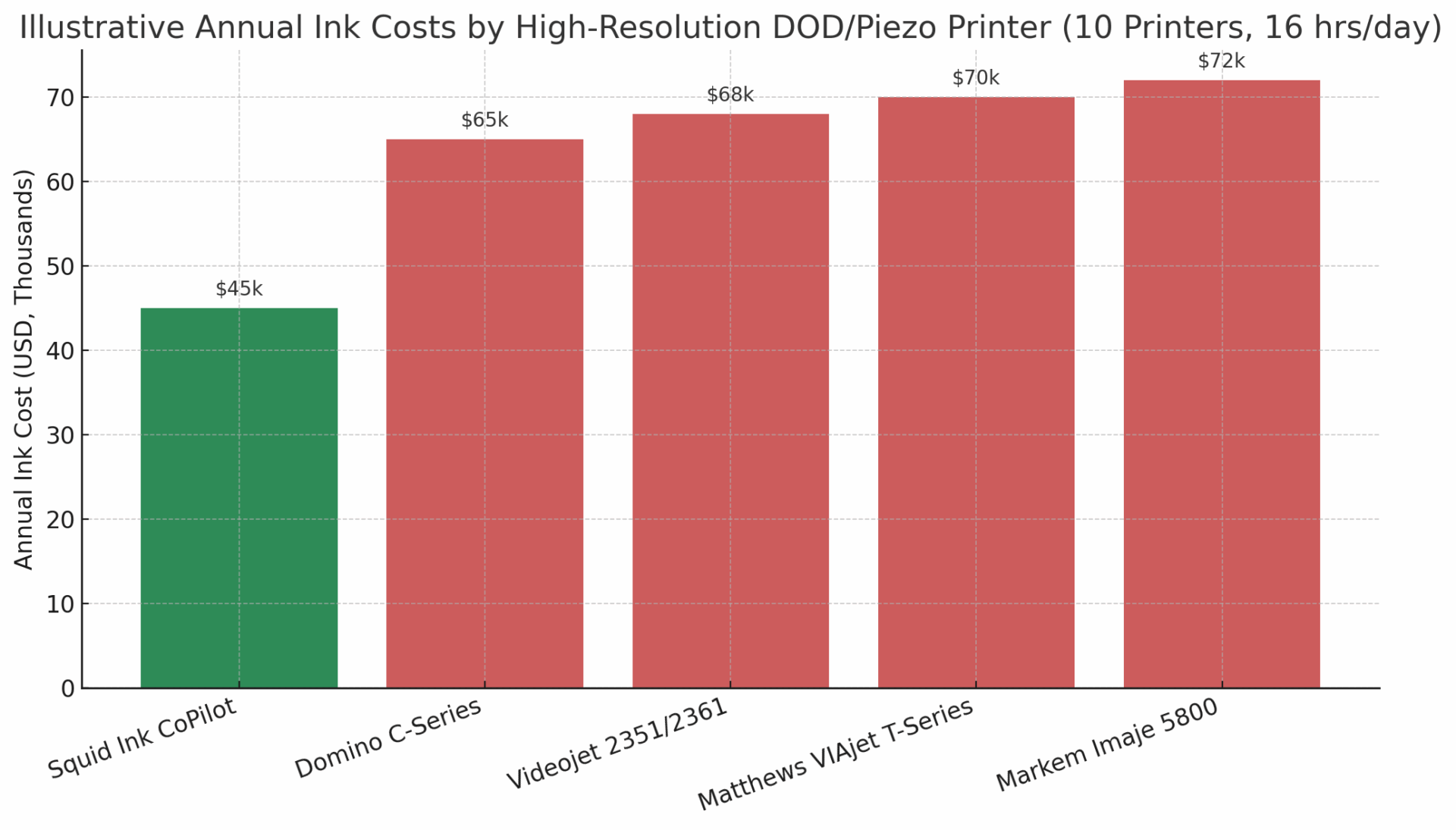

Ink System Economics

An open bulk ink design significantly reduces cost per liter compared to OEM-only systems. For high-volume plants running multiple lines, this translates into tens of thousands of dollars in annual savings.

- Squid Ink CoPilot: ~$45K per year

- Domino C-Series: ~$65K per year

- Videojet 2351/2361: ~$68K per year

- Matthews VIAjet T-Series: ~$70K per year

- Markem Imaje 5800: ~$72K per year

This chart illustrates how CoPilot’s open bulk ink system dramatically reduces consumable costs compared to proprietary OEM programs. Over multiple lines, this difference can equal hundreds of thousands of dollars annually.

Maintenance and Reliability

CoPilot requires little daily cleaning and no service contracts. Competitors often rely on service visits and scheduled downtime, increasing hidden ownership costs.

Conclusion

The Squid Ink CoPilot series, especially with the LT LongThrow option, delivers high-resolution printing, wide tolerance for real-world conditions and reduced consumable costs. Compared to Domino, Videojet, Matthews and Markem Imaje, CoPilot stands out as the most versatile and cost-effective option.

For manufacturers replacing labels or seeking to improve uptime, CoPilot LT provides:

- Wider throw tolerance (up to 12 mm) that reduces stoppages

- Open bulk ink savings compared to proprietary OEM systems

- Scalable coverage with stitchable heads and multiple ink chemistries

- Reliable performance at production speeds without constant maintenance

Pacific Labeling integrates and supports CoPilot solutions to ensure plants achieve maximum uptime and return on investment.

References

Domino Printing Sciences. “C-Series Plus Case Coders.” Domino Printing. 2023. https://www.domino-printing.com

Matthews Marking Systems. “VIAjet T-Series High Resolution Printers.” Matthews Marking. 2023. https://matthewsmarking.com

Markem Imaje. “5800 Touch Dry High Resolution Inkjet.” Markem Imaje. 2023. https://www.markem-imaje.com

Squid Ink Manufacturing. “CoPilot High Resolution Printers.” Squid Ink. 2023. https://squidink.com

Squid Ink Manufacturing. “CoPilot Max LT.” Squid Ink. 2023. https://squidink.com/products/hi-resolution-printers/copilot-max-lt/

Videojet Technologies. “2351 and 2361 Large Character High Resolution Printers.” Videojet. 2023. https://www.videojet.com