Presented by Pacific Labeling & Integration

Executive Summary

In modern supply chains labeling accuracy is critical. A single coding error can derail logistics, trigger expensive recalls and permanently damage brand reputation. Regulatory standards are stricter than ever and consumers demand transparency so companies cannot afford mistakes in coding and marking.

This paper explores the real cost of mislabeling, shares a case study on a costly recall, and details how Squid Ink, Norwix and Leibinger offer advanced printing technologies in DOD Piezo, TIJ and CIJ that safeguard compliance, reliability and brand trust.

The High Cost of a Simple Mistake

Coding and marking errors may appear minor such as a smudged lot number or an unreadable barcode but the consequences can be catastrophic:

- Financial losses: recalls can cost millions in disposal, logistics and fines

- Brand damage: consumers lose trust when safety and accuracy are compromised

- Operational disruption: recalled inventory disrupts supply chains and retail partnerships

- Legal liability: agencies like the FDA and USDA issue penalties for noncompliance

Case Example: A Food Recall That Went Wrong

In 2022 a national food brand faced a multi-million-dollar recall when thousands of units were mislabeled with incorrect allergen information. Distribution was halted, retailer relationships suffered, and consumer confidence eroded following widespread negative press. Labeling errors remain one of the top three causes of food recalls in North America proving that coding mistakes can have devastating consequences.

Why Accuracy Matters More Than Ever

- Regulatory compliance: FDA USDA and GS1 standards require precise legible codes for food pharma and consumer goods

- Retailer expectations: large retailers demand GS1 compliant barcodes for smooth inventory scanning

- Consumer transparency: customers expect accurate expiration dates allergen warnings and traceability

When codes fail it is not just a technical issue. It is a direct attack on consumer trust.

Technology That Prevents Mistakes

DOD Piezo: Squid Ink Hi-Resolution Systems

Squid Ink’s CoPilot uses Xaar piezo technology to print up to 0.7 inches of hi-resolution characters, razor-sharp text and scannable barcodes at 185 dpi. A 4.3-inch full-color touchscreen provides simple operation. Specifications include vertical resolution of 185 dpi, horizontal resolution of 205 dpi, speeds up to 135 feet per minute at 205 dpi and 200 feet per minute with optional high-speed printheads. The system supports oil-based or solvent-based inks for porous and non-porous substrates and offers bulk ink supply to reduce costs.

TIJ: Norwix and Squid Ink Viper

Norwix TIJ 4.0 systems offer high-speed 1200 dpi printing with a 22 mm print swath, bulk ink capability and speeds up to 600 feet per minute at 600 dpi. The PC22 model achieves 2400 fpm at 150 dpi with throw distances up to 7 mm. TIJ heads feature 4800 nozzles, 6 picoliter drop size, and 72 kHz firing frequency. Bulk ink systems further reduce consumable expenses. Squid Ink’s Viper TIJ leverages HP-style cartridges with integrated printheads to prevent clogging, prints at 600 x 600 dpi, supports line speeds above 500 fpm and simplifies operation through easy cartridge swaps.

CIJ: Leibinger Sealtronic Reliability

Leibinger’s CIJ printers feature Sealtronic nozzle sealing that prevents ink from drying during idle periods, ensuring instant startup. The IQJET model integrates smart ink management, automatic nozzle sealing and ink circulation to eliminate cleaning and downtime. The JET3 UP prints up to five lines at speeds of 403 meters per minute, uses Sealtronic to avoid clogging, and is configurable for food safety applications. CIJ systems operate at speeds up to 40 feet per second, printing on substrates including glass, metal, plastic, cable and film with specialty inks available for UV curing, pigmentation, heat resistance and food safety.

Business Case for ROI Through Accuracy

Investing in advanced coding systems leads to fewer errors, higher uptime and measurable cost savings:

- DOD Piezo (Squid Ink): cost-efficient case coding with bulk ink savings

- TIJ (Norwix and Squid Ink): GS1-compliant serialization and precision unit-level coding

- CIJ (Leibinger): maximum uptime and reliability in continuous high-speed operations

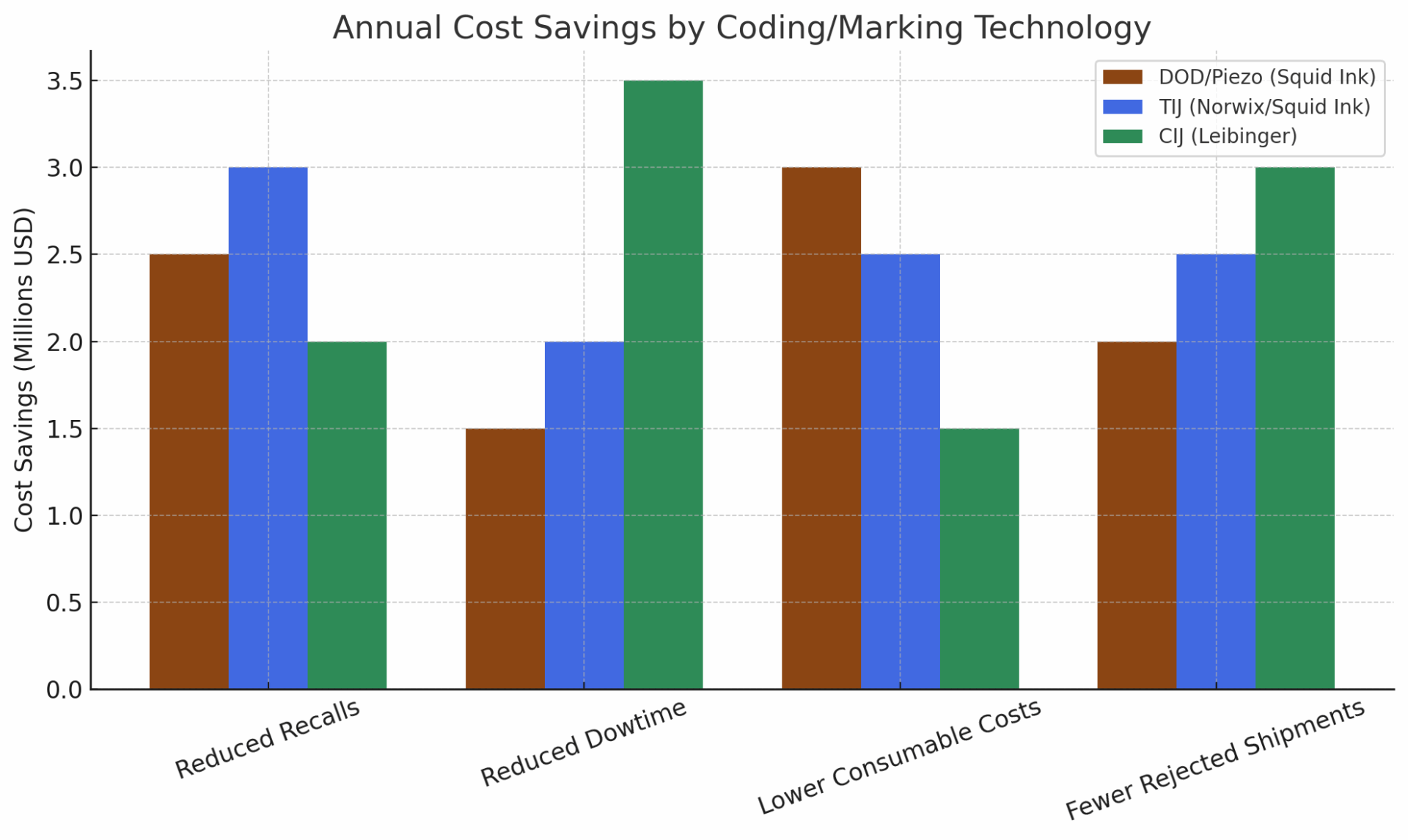

Annual Cost Savings by Technology

This chart compares annual savings in millions of dollars by technology type:

- DOD Piezo (Squid Ink) shown in brown

- TIJ (Norwix/Squid Ink) shown in blue

- CIJ (Leibinger) shown in green

The chart highlights how each technology reduces recalls, downtime, consumable costs and rejected shipments.

Conclusion

Coding and marking errors are high-stakes liabilities. With tightening regulatory demands and narrow margins manufacturers must eliminate misprints downtime and unreadable codes.

- DOD Piezo (Squid Ink) excels at cost-efficient case coding

- TIJ (Norwix/Squid Ink) delivers GS1-compliant serialization and precision unit-level coding

- CIJ (Leibinger) provides unmatched reliability for continuous high-speed production

Together these solutions safeguard compliance improve accuracy and preserve the reputation that brands have worked hard to build.

Pacific Labeling & Integration Puts It All Together

Pacific Labeling, Inc. partners with the world’s leading manufacturers to deliver cost-effective coding and marking solutions tailored to your industry. Contact us today to learn how the right system can protect your bottom line and safeguard your brand.

References

ID Technology. “IQJET Industrial CIJ Printer.” ProMach. https://www.idtechnology.com/products/iqjet-industrial-cij-printer

Leibinger Group. “Continuous Inkjet Printers (CIJ).” Leibinger. https://leibinger-group.com/cij-printer

Leibinger Group. “JET3 UP Continuous Inkjet Printer.” Leibinger. https://leibinger-group.com/printers/jet3-up

Marktec Products. “Xaar Technology Printers.” Marktec Products. https://marktecprods.com/marking-labeling-equipment/inkjet-printers-and-coders/small-character-product-coders-porous-and-non-porous/xaar-technology-printers

Matthews Marking Systems. “Case Studies: Improving Efficiency and ROI.” Matthews Marking. https://matthewsmarking.com/case-studies

Norwix. “PC22 Datasheet.” Norwix. https://norwix.com/wp-content/uploads/2023/02/PC22_0922_c.pdf

Norwix. “TIJ 4.0 Driver Solutions.” Norwix. https://norwix.com/tij4-driver-solutions

RN Mark. “Best Industrial Printer for Case Coding: TIJ vs DOD Piezo Comparison.” RN Mark. https://www.rnmark.com/best-industrial-printer-for-case-coding-tij-vs-dod-piezo-comparison

Kao Collins. “Advantages of TIJ Printing Over CIJ Printing.” Kao Collins. https://www.kaocollins.com/inktank/advantages-tij-printing-over-cij-printing

Squid Ink. “CoPilot Hi-Resolution Printers.” Squid Ink. https://squidink.com/products/hi-resolution-printers/copilot

Squid Ink. “CoPilot 128 Datasheet.”

Squid Ink. “CoPilot 128 Datasheet.” Squid Ink. https://squidink.com/products/hi-resolution-printers/copilot-128