Presented by Pacific Labeling & Integration

Leveraging Coding and Marking Technology to Maximize Efficiency and Reliability

Introduction

Across production floors, from beverage bottlers to fulfillment centers, one thing has become clear: the expectations for coding and marking systems are changing. Where once a date code or batch number was enough, today’s manufacturers face new demands: traceability regulations, sustainability goals, and the need for smarter, connected operations.

At Pacific Labeling & Integration, those challenges unfold daily. Conversations that used to revolve around “What prints where?” now ask “How does it integrate?” or “How often does it need service?” This shift has placed technologies from LEIBINGER, Squid Ink, and Norwix at the center of a new phase in industrial printing built on uptime, adaptability, and measurable efficiency.

Understanding Production Needs

The process usually starts with a few simple questions: What are you printing on? What kind of code is required? How connected is your line? The answers reveal everything.

| Key Question | Why It Matters | Impact on Printer Selection |

| What substrates are being printed on? | Porous, non-porous, coated, or mixed materials affect ink adhesion and drying time. | Determines ink type (solvent-based, UV-curable, aqueous). |

| What code types are required? | The industry is transitioning from 1D barcodes to 2D GS1 codes with embedded data. | Dictates print resolution and software compatibility. |

| How automated is the line? | Integration with MES/ERP systems and remote monitoring are becoming standard. | Guides selection toward printers with network connectivity. |

A regional beverage bottler in California discovered this firsthand. Their older printer struggled with condensation and surface variance between glass bottles and shrink-wrapped cans. When they installed a LEIBINGER IQJET with pigmented ink, code clarity improved immediately, and maintenance dropped to virtually zero. One system, properly matched to the materials, made all the difference.

Reliable Technology for Modern Demands

Reliability is often the deciding factor between production confidence and daily frustration. In one facility, a condiment manufacturer running multiple LEIBINGER systems found that the Sealtronic printhead design, where the ink circuit seals itself when idle, cut startup prep from half an hour to just minutes.

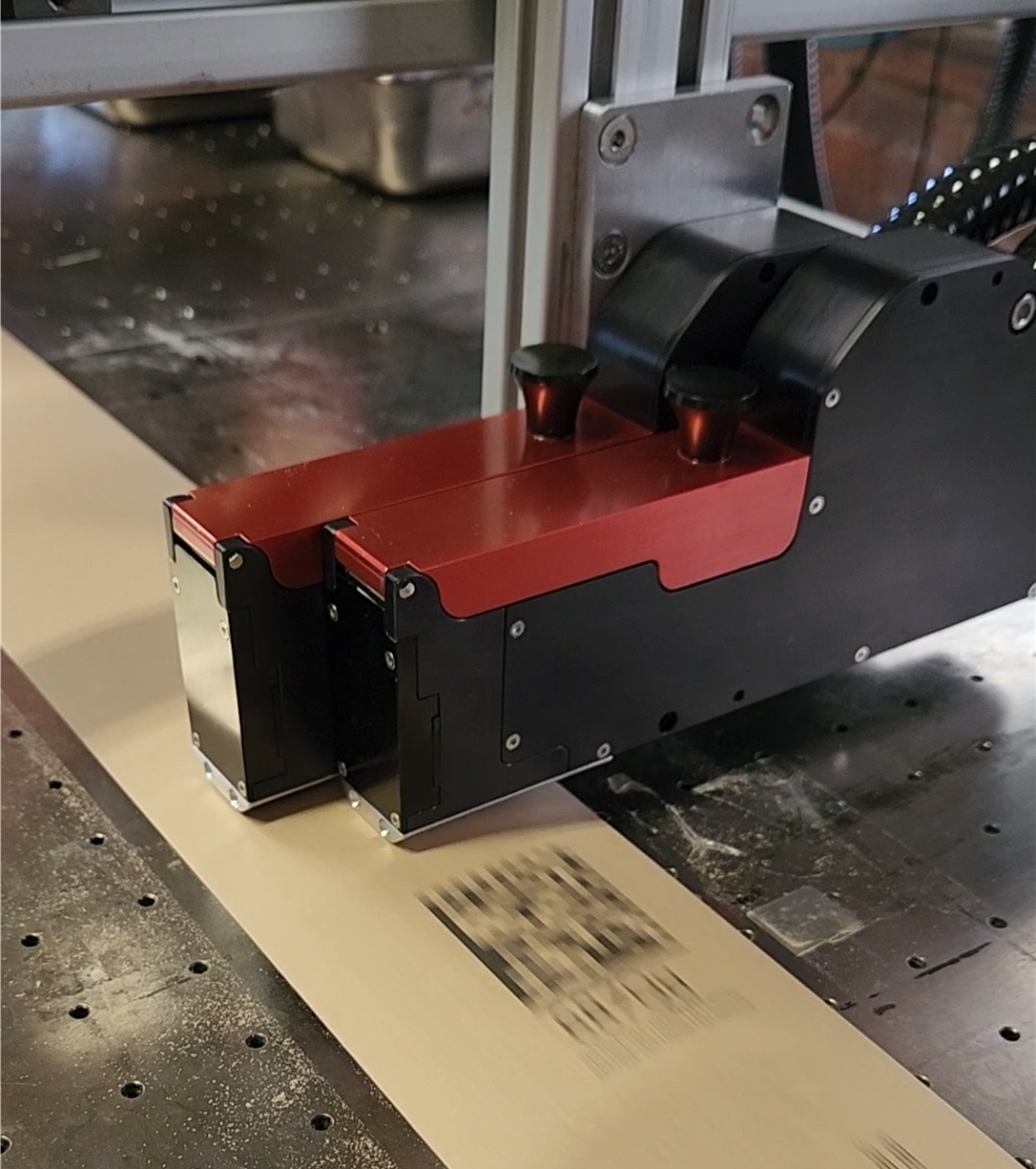

In another case, a packaging company switched to Squid Ink CoPilot Max printers. The modular design and simple maintenance meant operators could change printheads without calling in a technician. Over time, their spare parts orders dropped by nearly forty percent.

For operations built on speed and flexibility, Norwix thermal inkjet systems have become a quiet favorite. A fulfillment center that codes thousands of recycled boxes daily installed Norwix UC22 printers and eliminated all solvent waste while maintaining crisp, scannable prints.

Meeting Sustainability Expectations

Sustainability is no longer optional; it is a competitive requirement. LEIBINGER’s IQJET system consumes up to fifty percent less solvent than traditional continuous inkjet models. Squid Ink offers a growing range of low-VOC formulations for coated cartons and plastics, while Norwix focuses entirely on aqueous, environmentally safe inks.

An Oregon-based contract packager recently replaced aging CIJ printers with a LEIBINGER IQJET and Squid Ink CoPilot combination. Their yearly solvent use dropped by nearly four hundred gallons. Norwix users working on corrugated mailers achieved full compliance with California’s stringent VOC restrictions, keeping their sustainability promises to major retail partners intact.

Integration and Control

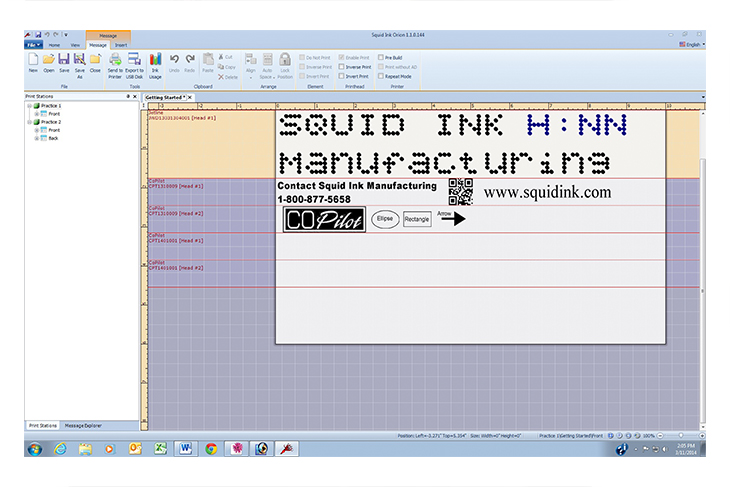

Production lines today are more connected than ever, and coding systems are following suit. LEIBINGER’s open API connects directly to ERP and MES platforms, allowing operators to push batch data automatically to every printer. Squid Ink’s Orion software centralizes print management, enabling real-time updates and error-proofing for multi-printer setups. Norwix’s network-ready systems simplify installation and remote monitoring for smaller facilities with fewer IT resources.

At one global snack producer, integrating LEIBINGER CIJ printers into their ERP system reduced human input errors by ninety-five percent. A logistics warehouse using Squid Ink’s Orion platform now monitors all printheads from a single control station, ensuring consistent results across several packaging lines.

Reducing Waste and Downtime

| Area of Efficiency | Typical Reduction | Primary Contributors |

| Maintenance time | 30–60% | Self-sealing printheads, cartridge-based systems |

| Solvent/ink consumption | 25–50% | Efficient ink management, low-VOC formulations |

| Line downtime | 20–40% | Remote monitoring, predictive alerts |

| Consumable waste | 15–30% | Consistent droplet control and ink efficiency |

One food manufacturer running ten production lines calculated that switching to LEIBINGER and Squid Ink systems saved thirty-two hours of downtime per month, roughly $14,000 in reclaimed productivity.

Scalable Systems for Growth

Production never stands still. As facilities expand, so must their printing infrastructure. LEIBINGER CIJ systems handle everything from small character codes to high-speed beverage lines without replacement. Squid Ink’s modular architecture lets businesses start small and scale to full-panel printing by adding synchronized printheads. Norwix’s cartridge-based TIJ systems fit perfectly in short-run or multi-SKU environments where fast changeovers are vital.

A spice producer in Texas started with one Squid Ink CoPilot Max. Within months, the system expanded into a four-head network controlled by Orion software. Across the country, a cosmetics manufacturer scaled from one Norwix printer to six across its filling and labeling stations, maintaining uniform lot codes with centralized control.

The Human Element

Hardware alone does not guarantee success. Ink formulation, substrate testing, and maintenance planning are what separate a temporary fix from a lasting solution. Each manufacturer brings something distinct:

| Expertise Area | LEIBINGER | Squid Ink | Norwix |

| Ink management | Closed, sealed systems reduce solvent use | Broad ink portfolio for porous and non-porous materials | Cartridge-based aqueous inks for low VOC output |

| Service approach | Preventive design minimizes service needs | Easy-to-service modular architecture | Virtually maintenance-free operation |

| Application focus | High-speed, harsh environments | Flexible case and carton printing | Short-run, variable data production |

In one electronics facility, pigment-based LEIBINGER systems nearly eliminated nozzle blockages that once caused misprinted serial codes. A warehouse using Squid Ink’s certified inks saw dramatic improvements in print contrast on recycled corrugate. A packaging converter using Norwix transitioned to water-based inks and ended complaints about solvent odor and storage.

The Outcome

When manufacturers select printing systems that match their workflow, they gain more than reliability; they gain time, consistency, and control. The evolution of coding and marking is not about bigger, faster machines but about smarter integration and lower total cost of ownership. Whether it is a LEIBINGER CIJ on a beverage line, a Squid Ink case coder on a packaging line, or a Norwix TIJ in a fulfillment center, each system reflects a broader shift toward precision, sustainability, and accountability.

References

Norwix Application Notes and Resources (2024)

https://norwix.com/content/

Ready for Tomorrow: Coding and Marking on Any Material – LEIBINGER Group (2024)

https://leibinger-group.com/news/ready-for-tomorrow-coding-and-marking-on-any-material

Coding and Marking Market Outlook Report 2024–2030 – Finance Yahoo Research (2024)

https://finance.yahoo.com/news/coding-marking-market-outlook-report-084100143.html

The Complete Guide to Industrial Inks and Solvents from LEIBINGER, Squid Ink, and Norwix – USInks.com (2024)

https://usinks.com/blogs/news/the-complete-guide-to-industrial-inks-and-solvents-from-leibinger-squid-ink-and-norwix

CoPilot Max Turbo High-Resolution Printing System – Squid Ink via MarkPack Inc. (2024)

https://markpackinc.com/product/squid-ink-copilot-max-turbo-printing-system/

Case Coding Solutions – Norwix (2024)

https://norwix.com/case-coding/

IQJET Continuous Inkjet Printer Technical Brochure – LEIBINGER Group (2024)

https://leibinger-group.com/printers/iqjet

Orion Software Overview – Squid Ink Manufacturing (2023)

https://squidink.com/vcts-copilot-max-turbo/

Aqueous and Low-VOC TIJ Ink Applications – Norwix Technical Data Sheet (2024)

https://norwix.com/tij4-driver-solutions/

LEIBINGER IQJET Case Study – “Four Peaks and LEIBINGER: The Craft of Beer and the Art of Coding” (2024)

https://leibinger-group.com/case/four-peaks-and-leibinger-craft-beer-and-art-of-coding

LEIBINGER User/Testimonial Case Study – “Ensuring High-Speed Efficiency: Encore Wire Relies on LEIBINGER” (2024)

https://leibinger-group.com/cij-technology-leader

Squid Ink Application Report – “Helping La Fermière with Packaging Code Quality” (2023)

https://dartronics.com/squid-ink-case-study-on-helping-premiere-yogurt-brand/

Norwix Customer Feedback Report – “High Speed, High Resolution TIJ 4.0 Print Solution” (2024)

https://norwix.com/wp-content/uploads/2023/02/PC22_0922_c.pdf

Pacific Labeling Field Report – “TIJ vs CIJ: A Practical Guide to Choosing the Right Printer for Your Packaging Line” (2024)

https://pacificlabeling.com/tij-vs-cij-a-practical-guide-to-choosing-the-right-printer-for-your-packaging-line/

USInks.com Sustainability Report (2024)

https://usinks.com/pages/sustainability

LEIBINGER Automation/Integration Brief – “Reducing Costs and Enhancing Productivity in the Food and Beverage Industry” (2024)

https://atduk.com/blog/reducing-costs-and-enhancing-productivity-in-the-food-and-beverage-industry-leibinger-iqjet/

Squid Ink Integration Case Study – “CoPilot Max 512i Turbo Printing System” (2023)

https://www.snackandbakery.com/articles/97608-squid-ink-manufacturing-copilot-max-512i-turbo-printing-system

Pacific Labeling Client Data (2024)

https://pacificlabeling.com/tij-vs-cij-a-practical-guide-to-choosing-the-right-printer-for-your-packaging-line/

Squid Ink Customer Report – “Large Character Printers: Get Big with SQUID!” (2023)

https://dartronics.com/large-character-printers-get-big-with-squid/

Norwix Case Summary (2024)

https://norwix.com/

LEIBINGER Technical Feedback (2024)

https://leibinger-group.com/media-library

Squid Ink Support Resources (2023)

https://squidink.com/support/