Presented by Pacific Labeling & Integration

Expanded White Paper: LEIBINGER IQJET vs Major CIJ Competitors

Executive Summary

Continuous Inkjet (CIJ) printers remain the most widely adopted coding and marking technology across packaging and manufacturing lines. For industries such as food, beverage, pharmaceuticals and consumer goods, CIJ printers provide date codes, lot codes, barcodes and regulatory information that keep products compliant and traceable. Yet CIJ systems often carry a reputation for maintenance issues, solvent consumption and downtime that reduce productivity.

This paper provides a detailed, feature by feature comparison of the LEIBINGER IQJET CIJ printer with four of the most prominent competitor systems: Videojet 1580/1880 Plus, Domino Ax Series, Markem Imaje 9000 Series and Keyence MK G1000. It goes beyond specifications by examining the real-world consequences of each design choice. The purpose is to equip operations managers, plant engineers and purchasing decision makers with evidence-based insight to select the most reliable and cost-effective CIJ solution.

Overview of the LEIBINGER IQJET

The LEIBINGER IQJET was designed to solve nozzle clogging, one of the most persistent issues in CIJ printing. Standard CIJ systems rely on open nozzles where solvent-based inks dry, forcing operators to perform daily cleaning or flushing. IQJET eliminates this with Sealtronic nozzle-sealing technology, which fully seals the nozzle when idle. This prevents drying inside the printhead and allows the printer to restart instantly without priming or rinsing.

In high-volume plants where lines may stop and start several times per shift, Sealtronic can save several minutes per stop. Across a 24/7 environment these recovered minutes become hours of regained uptime each year. That improvement boosts throughput while reducing labor involvement and solvent waste.

IQJET also supports up to eight high-resolution print lines, compared to the five lines typical of competitors. This flexibility allows manufacturers to print more product details or apply complex layouts without adding hardware.

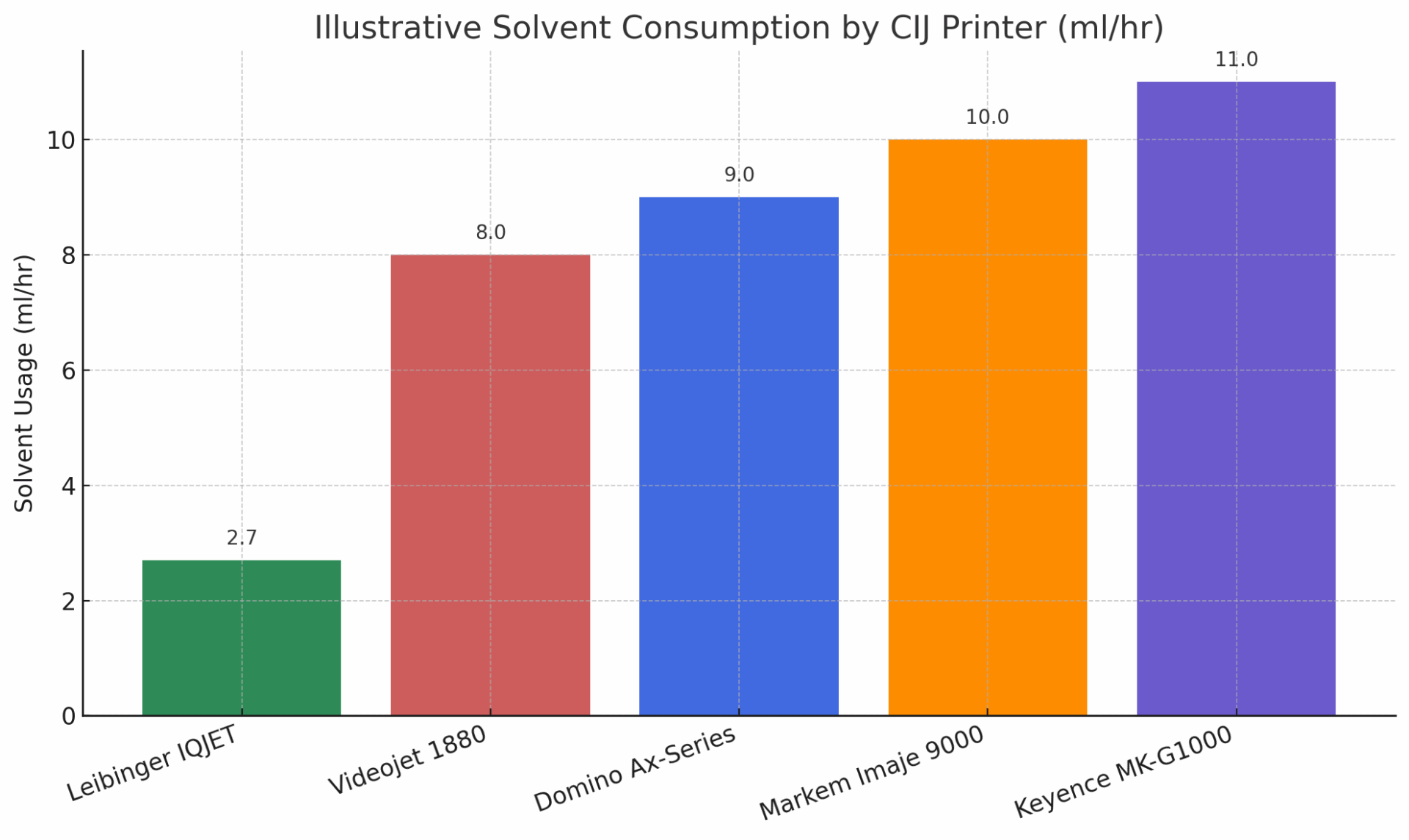

Efficiency is another key advantage. IQJET achieves up to 500 hours of runtime per ink fill and solvent consumption rates as low as 2.7 ml per hour. Competing models often consume two to four times that amount, leading to higher consumable costs and more frequent operator intervention.

Solvent Efficiency in Context

The chart below illustrates solvent consumption across the IQJET and major competitors.

This comparison highlights how IQJET’s sealed nozzle design and optimized ink circuit deliver superior efficiency. Over thousands of hours, lower solvent usage reduces both cost and environmental impact. Data adapted from manufacturer specifications and industry benchmarks.

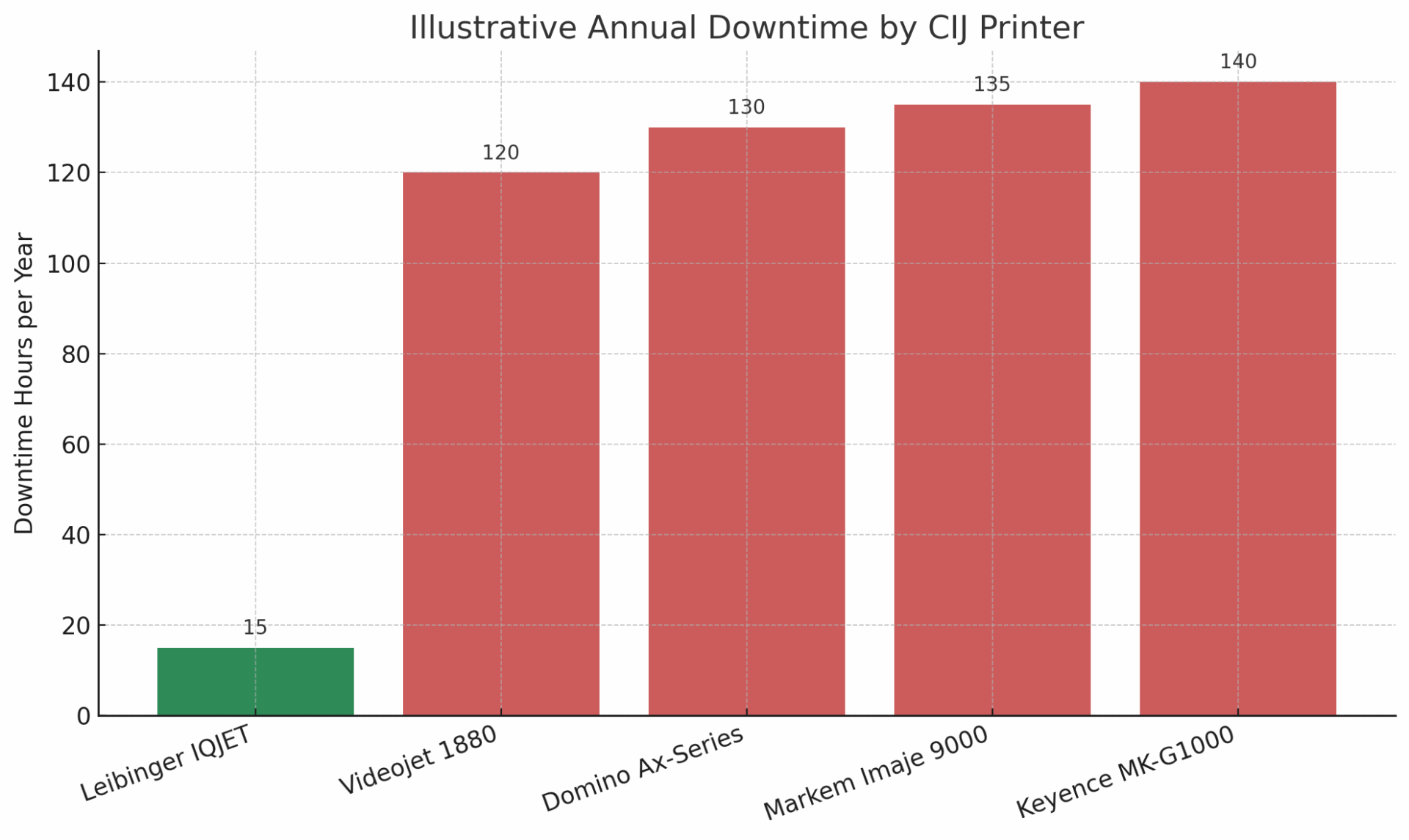

Downtime Advantage in Context

Competitor printers such as Videojet, Domino, Markem Imaje and Keyence can lose more than 120 hours annually to nozzle clogs, cleaning cycles and maintenance. IQJET, with Sealtronic nozzle sealing, reduces downtime to about 15 hours per year.

This is not just an incremental improvement. It is a step change that can recover entire weeks of production time each year. That level of uptime improvement makes the IQJET not just a printer but a productivity tool that drives profitability.

Competitor Landscape and Feature Comparisons

The CIJ market is led by brands like Videojet, Domino, Markem Imaje and Keyence. While their systems offer acceptable print quality for basic coding, they share several design limitations.

The following table outlines the differences between the IQJET and its competitors. Below the table, each category is explained in detail to highlight how these features affect daily production.

| Feature | LEIBINGER IQJET | Videojet 1580 / 1880 Plus | Domino Ax Series | Markem Imaje 9000 Series | Keyence MK G1000 |

|---|---|---|---|---|---|

| Print Quality & Lines | Up to 8 high-resolution lines | Up to 5 lines | Up to 5 lines | Up to 5 lines | Up to 6 lines |

| Nozzle Sealing | Sealtronic airtight | CleanFlow reduces buildup only | Standard nozzle, prone to drying | Reduced buildup design | Auto shower cleaning |

| Daily Cleaning | None required | Regular cleaning required | Cleaning cycles required | Periodic cleaning required | Periodic cleaning required |

| Solvent Efficiency | 2.7 ml/hr | Higher usage | Higher usage | Higher usage | Higher usage |

| Power Usage | 36 W | Higher | Higher | Higher | ~150 W |

| Startup Time | Instant start | 6–10 minutes | Several minutes | Several minutes | Several minutes |

| Maintenance | Up to 5 years between PMs | Contracts common | Regular service required | Contracts common | Service required |

| Interface | Industrial UI with smart alerts | 10.4-inch guided | Guided UI | Touchscreen | 10.4-inch guided |

| Air Requirements | None | Some models | Some models | Some models | Some models |

| Build Quality | Stainless steel IP56/IP66 | IP55/IP66 mix | IP55/IP66 mix | IP55/IP66 mix | IP55 |

| Component Sourcing | 85% in-house | Mostly third party | Significant outsourcing | Significant outsourcing | Significant outsourcing |

| Origin | Germany | Global | Global | Global | Japan |

What These Differences Mean

Print Quality and Lines

IQJET supports up to eight high-resolution lines of code, while most competitors max out at five or six. In practice, this means the IQJET can print a product name, lot number, expiry date, barcode and even promotional text in one pass. Competitors often require an extra printer or simplified code layout to achieve the same.

Nozzle Sealing

Sealtronic is the only technology that fully seals the nozzle airtight. Competitor methods reduce buildup but still allow drying, which means operators must clean the nozzle daily or accept inconsistent print quality. This difference directly affects uptime.

Daily Cleaning

IQJET requires no daily cleaning. Competitors may need rinsing cycles, manual wipes or flushing. Over the course of a year, this adds up to dozens of hours of lost production and hundreds of dollars in solvent.

Solvent Efficiency

IQJET’s 2.7 ml/hr solvent usage is a fraction of competitors, some of which use three to four times more. For plants running 10 or more printers, this difference translates into tens of thousands of dollars saved annually in consumables.

Power Usage

At 36 watts, IQJET draws less energy than many office lightbulbs. Competitors often exceed 100 watts and Keyence approaches 150 watts. In a large-scale facility this adds significantly to energy costs and carbon footprint.

Startup Time

IQJET starts instantly. Competitors can take 6–10 minutes or longer due to priming and rinsing cycles. In environments with frequent stops and starts, those minutes compound into hours of lost productivity.

Maintenance

IQJET can run up to five years without preventive maintenance. Competitors often rely on service contracts, requiring technician visits every 6–12 months. This means IQJET not only reduces downtime but also lowers hidden service costs.

Interface

The IQJET uses an industrial-grade touchscreen with smart alerts that notify operators before issues become problems. Competitors offer guided interfaces, but they still require more intervention and lack predictive maintenance tools.

Air Requirements

IQJET requires no plant air. Many competitors need compressed air for ink systems, which adds cost, complexity and maintenance of air lines and compressors.

Build Quality

IQJET is constructed with stainless steel IP56/IP66 housings, ensuring resilience against dust and water. Competitors often use mixed materials or plastic parts that may degrade faster in harsh environments.

Component Sourcing and Origin

With 85% of its parts made in-house in Germany, IQJET ensures consistent quality and supply chain stability. Competitors rely heavily on third-party suppliers spread across global facilities, which can impact parts availability and long-term support.

Detailed Advantages of the IQJET

- Sealtronic Nozzle Sealing

Eliminates nozzle drying, clogs and cleaning cycles. Improves uptime, reduces labor and solvent waste and ensures consistent print quality. - High Print Capacity

Supports up to eight print lines, more than most competitors, enabling complex or multi-message coding without extra equipment. - Energy Efficiency

At 36 watts the IQJET consumes significantly less power than competitors that draw more than 100 watts, reducing electricity costs over long shifts. - Minimal Maintenance

Runs up to five years without preventive maintenance, eliminating service contracts and freeing staff for higher-value work. - German Manufacturing

With more than 85 percent of components produced in-house, LEIBINGER maintains strict quality standards and supply stability, unlike competitors who outsource extensively.

Conclusion

The LEIBINGER IQJET does more than improve coding and marking. It redefines what manufacturers should expect from a CIJ printer. By sealing the nozzle when idle it eliminates the chronic problem of clogs and cleaning cycles that plague traditional systems. Its solvent usage is a fraction of competitors, its energy consumption is the lowest in its class and its ability to run for up to five years without preventive maintenance breaks the cycle of costly service contracts.

These advantages translate into measurable results:

- Higher uptime and fewer line stoppages

- Lower consumable and energy costs

- Consistent code quality that protects brand reputation

- Long-term reliability backed by German engineering and in-house manufacturing

For operations leaders, engineers and procurement teams the decision is clear. Competing printers may meet basic coding needs but they cannot match the combination of efficiency, durability and total cost savings delivered by the IQJET. In a market where minutes of downtime equal thousands of dollars lost, choosing the wrong printer is a liability. Choosing the IQJET is an investment in productivity, sustainability and peace of mind.

References

ID Technology. “IQJET Industrial CIJ Printer.” ProMach. 2023. https://www.idtechnology.com/products/iqjet-industrial-cij-printer

Leibinger Group. “Continuous Inkjet Printers and Automatic Nozzle Sealing.” Leibinger. 2023. https://leibinger-group.com/cij-printer

Matthews Marking Systems. “The ROI of Preventive Maintenance for Inkjet Printers.” Matthews Marking. 2019. https://matthewsmarking.com

Matthews Australasia. “The True Cost of Downtime and How to Minimise It.” Matthews. 2024. https://www.matthews.com.au/blog/the-true-cost-of-downtime-and-how-to-minimise-it

Moss T, Pattison J. “The Hidden Costs of Downtime in Manufacturing.” Manufacturing Global. 2021. https://manufacturingglobal.com

Videojet Technologies. “Videojet 1880 Continuous Inkjet Printer.” Videojet. 2023. https://www.videojet.com

Domino Printing Sciences. “Ax-Series Continuous Inkjet Printers.” Domino Printing. 2023. https://www.domino-printing.com

Markem Imaje. “9000 Series CIJ Printers.” Markem Imaje. 2023. https://www.markem-imaje.com

Keyence. “MK-G1000 Continuous Inkjet Printer.” Keyence. 2023. https://www.keyence.com

Charts Created By Author Using Data from Manufacturer Specifications and Industry Benchmarks:

Illustrative Annual Downtime Comparison: IQJET vs Competitors

Illustrative Solvent Consumption by CIJ Printer (ml/hr)