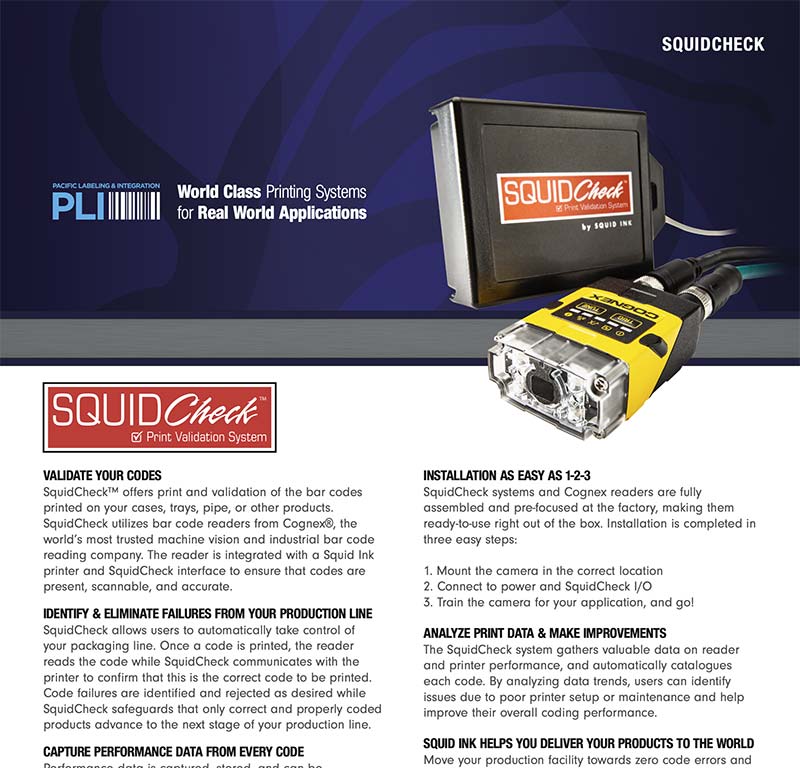

Squid Ink SquidCheck Print Validation System

Take control of your coding accuracy.

The SquidCheck Print Validation System gives you peace of mind by ensuring every print on your line is present, properly placed, and readable. Designed to work seamlessly with Squid Ink’s entire product line, SquidCheck automatically inspects your codes—catching errors before they leave your facility.

Maximize Your Marking Potential

From missed prints to misaligned barcodes, SquidCheck reduces waste, protects your brand, and saves time by automating what used to be a manual QC step. It’s a smarter way to validate your prints without slowing down production.

Why Choose the SquidCheck Print Validation System?

Ensures Print Presence and Quality

Detects missing, smudged, or unreadable codes instantly

Compatible With Squid Ink Printers

Seamlessly integrates with CoPilot, JetStream, VDP, and more

Flexible Mounting Options

Easy installation on a variety of packaging lines

Instant Fault Detection

Triggers alarms or line stops when an error is found

Improves Compliance and Traceability

Ideal for industries with strict print requirements

Reduces Waste and Rework

Catches print errors in real time to minimize scrap and costly production delays

Designed for High-Volume, Fast-Paced Production

From food and beverage to industrial packaging and pharmaceuticals, the CoPilot Max Turbo is built for reliable, high-speed performance in demanding environments. Its rugged construction and active ink delivery systemensure consistent quality with minimal downtime.

Upgrade to High-Resolution Printing Today!

As an authorized Squid Ink reseller and service provider, Pacific Labeling & Integration offers expert support, competitive pricing, and fast shipping to keep your operation moving. Contact us today to learn more about the CoPilot Max Turbo or to schedule a demo.

How Can We Help?

As an authorized reseller, distributor, and service center for Squid Ink, Pacific Labeling provides expert support for the Squid Ink Co-Pilot Max Turbo printer. From installation to maintenance, we ensure seamless performance with fast service, genuine parts, and industry-leading expertise to keep your production running smoothly.