Presented by Pacific Labeling & Integration

Rethinking Coding in Packaging Lines

Historically, Continuous InkJet (CIJ) printers were the go-to solution for printing lot codes, barcodes, and expiration dates on packaging. Their ability to print on various materials made them appealing. But they also brought complexity — high maintenance, solvent fumes, and excessive downtime.

Today, Thermal InkJet (TIJ) technology offers a cleaner, smarter, and lower-cost alternative. At Pacific Labeling, we help companies replace outdated CIJ setups with next-generation TIJ systems that deliver sharp, consistent results without the mess or headaches.

CIJ vs TIJ at a Glance

| Feature | CIJ | TIJ |

|---|---|---|

| Maintenance | High | Low |

| Ink Handling | Messy solvents | Clean sealed cartridges |

| Startup Time | Long | Instant |

| Print Quality | Moderate | High resolution |

| Cost of Ownership | High | Low |

How CIJ and TIJ Work

CIJ Basics

CIJ printers jet a continuous stream of ink droplets through a nozzle. Most droplets are recycled while only a few are deflected to the packaging surface. The system requires constant solvent balancing and uses multiple pumps, valves, and filters.

TIJ Basics

TIJ uses disposable cartridges where heat causes a tiny ink bubble to form, ejecting a droplet onto the substrate. Each cartridge acts as a clean, self-contained print system — no external ink tanks or fluid adjustments needed.

TIJ Advantages:

- High-resolution barcodes and text

- Clean operation

- Minimal operator training

- Compact footprint

- Environmentally friendly (no VOC-heavy solvents)

CIJ Advantages:

- Works well on irregular surfaces

- Strong throw distance

Cost Comparison

Capital Cost

CIJ printers average over $9,500 due to their complexity. TIJ systems like the Norwix .UNO or Viper from Squid Ink start around $5,000, nearly half the price.

Equipment Cost Comparison

- CIJ: $9,500+

- TIJ: $5,000

Operational Costs

While CIJ ink is cheaper per liter, TIJ delivers better control over ink usage. TIJ cartridges reduce waste, and resolution settings let users adjust ink usage based on print needs.

Result: Over time, cost per print is nearly equal, but TIJ avoids hidden expenses like service contracts, fluid evaporation, and unplanned downtime.

Maintenance, Uptime, and Line Impact

Downtime

CIJ systems need regular cleaning, filter changes, and service. TIJ printers require none. Every new cartridge refreshes the print system.

Downtime Types:

- Unscheduled: due to CIJ failures

- Scheduled: routine CIJ maintenance

- Non-Scheduled: idle time where CIJ is left on, wasting fluids

Downtime Comparison

| Metric | CIJ | TIJ |

|---|---|---|

| Startup Time | 10–15 minutes | Instant |

| Service Frequency | Weekly or Monthly | Never |

| Fluid Loss | High (open system) | None (closed cartridge) |

Estimated Annual Maintenance Cost:

- CIJ: ~$3,000

- TIJ: $0

Substrate Compatibility and Applications

CIJ was once favored for printing on non-porous materials due to MEK-based ink. Now, TIJ cartridges are available with solvent-based formulas that perform just as well — without the mess or complexity.

Materials Now Supported by TIJ:

- Plastics

- Foils

- Films

- Coated cartons

- Metal cans

TIJ is now a viable CIJ replacement across most packaging environments.

Industries PLI Supports with TIJ:

- Food and Beverage

- Pharmaceuticals

- Nutraceuticals

- Cosmetics and Personal Care

- Contract Packaging

- Electronics and Cabling

- Logistics and Warehousing

Application Fit by Printer Type

| Use Case | CIJ | TIJ (Norwix / Squid) |

|---|---|---|

| Bottle Coding | ✔️ | ✔️ |

| Box Barcodes | ✔️ | ✔️ |

| Cables & Tubing | ✔️ | ✔️ |

| Trays & Sleeves | ✔️ | ✔️ |

TIJ Solutions from Pacific Labeling

TIJ has matured into a high-performance alternative to CIJ, and Pacific Labeling offers two proven solutions.

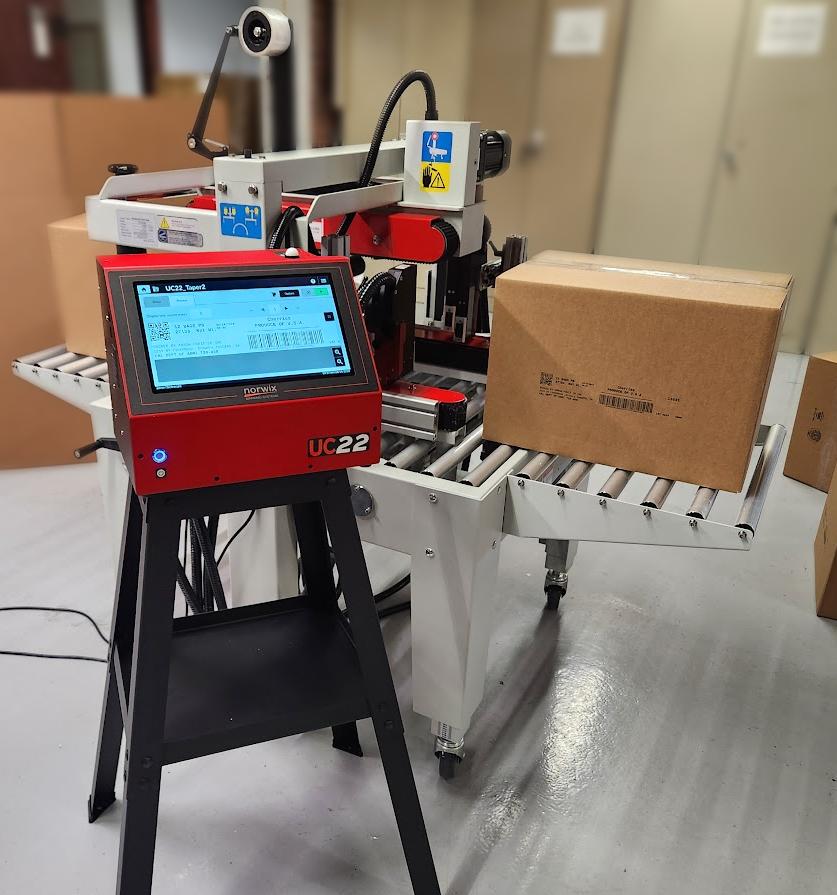

Norwix .UNO

- 7-inch touchscreen with integrated printhead

- Ultra-compact design

- ½ inch print height

- Perfect for barcodes, date codes, lot codes

- Plug-and-play with minimal training required

Squid Ink Viper TIJ

- Robust, cartridge-based thermal inkjet

- Modular design for flexible integration

- Compatible with porous and coated materials

- Great for secondary packaging

- Clean prints and easy changeover

8 Reasons to Replace CIJ with TIJ

- No ink mess

- No solvent fumes

- Zero maintenance

- More reliable coding

- Lower total cost

- Simpler operation

- Cleaner for your team

- Fits smaller lines and workspaces

Why Pacific Labeling

Pacific Labeling doesn’t just sell printers — we’re here to help you optimize your production line.

- Expert consultation to choose the right solution

- Seamless installation and employee training

- Real-time support when and where you need it

- 14-day in-plant trials available on Norwix and Squid Ink TIJ systems

- Full integration with labeling equipment and existing lines

Want to see TIJ in action?

Visit pacificlabeling.com or contact our team today for a free demo or trial unit.